Physical Address

Arthur Avenue , BrookField , ILLINOIS , 60513 , United State

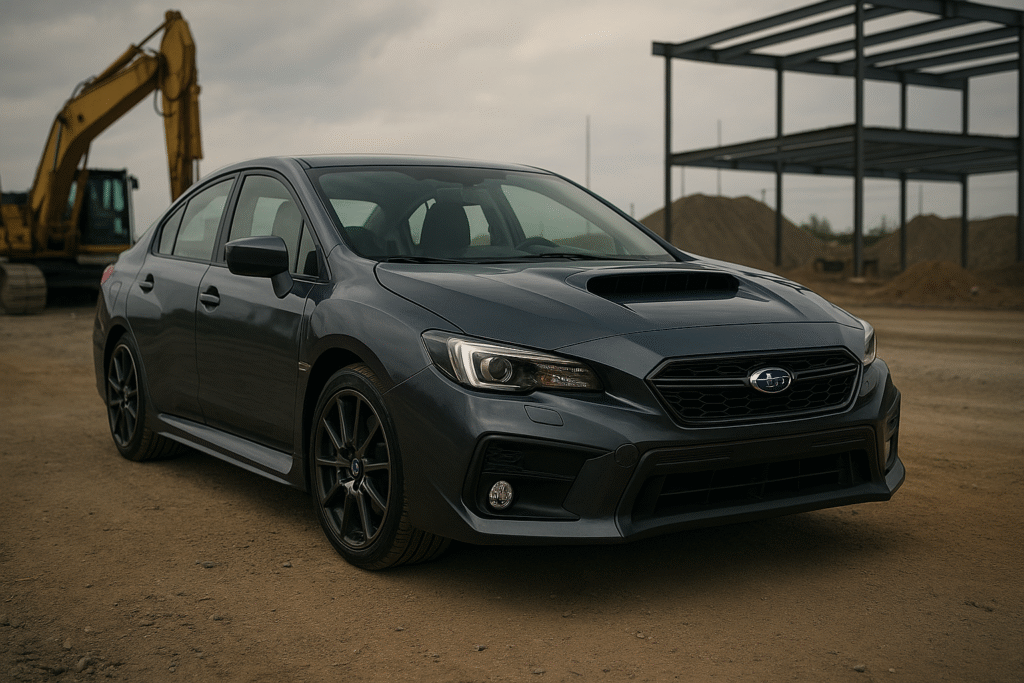

A Subaru boxer engine rolls into the bay with that unmistakable low, pulsing exhaust note — the sound that every technician recognizes instantly. Below the car, you see the horizontally opposed cylinders sitting low in the chassis, flanked by equal-length driveshafts. This is not another generic platform shared across five brands. Subaru builds its vehicles around a mechanical identity that prioritizes balance, predictability, stability on bad roads, and driver confidence in any weather.

For engineers, technicians, and heavy-equipment specialists, Subaru represents the intersection of aviation-influenced engineering, rally testing, and practical real-world durability. Its vehicles are built for regions where weather is a factor, roads aren’t always smooth, and drivers rely on mechanical fidelity rather than electronic band-aids.

This article provides a complete professional breakdown of “Subaru – Boxer Engines, Symmetrical AWD & Rally Legacy.” It covers engineering philosophy, drivetrain design, maintenance implications, failure modes, safety systems, materials, manufacturing, and real technical insights relevant to workshops. As always, it concludes with tables, FAQs, and recommended reading at cartechexpert.com and professional resources at store.cartechexpert.com.

This phrase captures three pillars that define Subaru’s engineering DNA:

For technicians, this means Subaru vehicles behave differently, wear differently, and require different inspection techniques than transverse-engine FWD-based competitors.

Subaru’s engineering culture originates from its aerospace roots. Fuji Heavy Industries — Subaru’s parent — built aircraft before it built cars, and that influence shows in:

In the 1990s and 2000s, Subaru’s rally program transformed the brand’s identity. The Impreza WRX and WRX STI became global icons. Lessons from rally — heat management, drivetrain durability, suspension control, and modular serviceability — filtered directly into road cars.

Subaru’s boxer engine is its single most distinguishing mechanical feature. Instead of an inline or V-type layout, the cylinders oppose each other horizontally. This provides:

Subaru’s AWD system is not an optional add-on; it is a core architectural decision. Unlike most competitors who adapt AWD onto a FWD platform, Subaru begins with longitudinal engine placement and symmetrical power delivery.

This yields predictable traction on wet, icy, loose, or uneven surfaces. For technicians, it also means more drivetrain components to inspect — but components that are logically arranged.

Subaru’s rally success was built on durable drivetrains, balanced chassis, and engines capable of absorbing constant load variation. Rally engineering influences:

Modern Subaru SUVs and sedans still inherit rally principles: confidence on poor roads, quick steering, predictable AWD torque transfer, and strong structural shells.

The Subaru Global Platform (SGP) underpins recent models, focusing on rigidity, ride comfort, and crash performance.

Known for longevity and smoothness, but sensitive to oil quality.

Subaru vehicles operate widely in snow regions, requiring superior anti-corrosion strategies:

| Type | Advantages | Service Risks |

|---|---|---|

| NA Boxer | Smooth, reliable | Head gaskets, oil leaks |

| Turbo Boxer | Performance, torque | Detonation risk, heat management |

| Hybrid | Efficiency | HV safety, coolant control |

| Component | Check Frequency | Notes |

|---|---|---|

| Differentials | Every major service | Fluid condition critical |

| CV Boots | Every inspection | Split boots = rapid wear |

| Center Coupling | As needed | Symptoms: binding, noise |

Because they deliver low center of gravity, inherent balance, and AWD packaging advantages.

It requires more components than FWD, but is reliable if fluids and boots are serviced on schedule.

Modern models have excellent coatings, but snow-belt vehicles should be washed underneath routinely.

Turbo boxer power, rally heritage, and symmetrical AWD dynamics.

Read more at cartechexpert.com and explore professional workshop tools at store.cartechexpert.com.

Subaru’s engineering identity has remained remarkably consistent: boxer engines, symmetrical AWD, and real-world durability shaped by rally and harsh-climate performance. For technicians and engineers, these systems provide predictable behavior, but require specialized knowledge of fluid maintenance, gasket inspection, AWD balancing, and chassis alignment.

Thank you for reading.