Physical Address

Arthur Avenue , BrookField , ILLINOIS , 60513 , United State

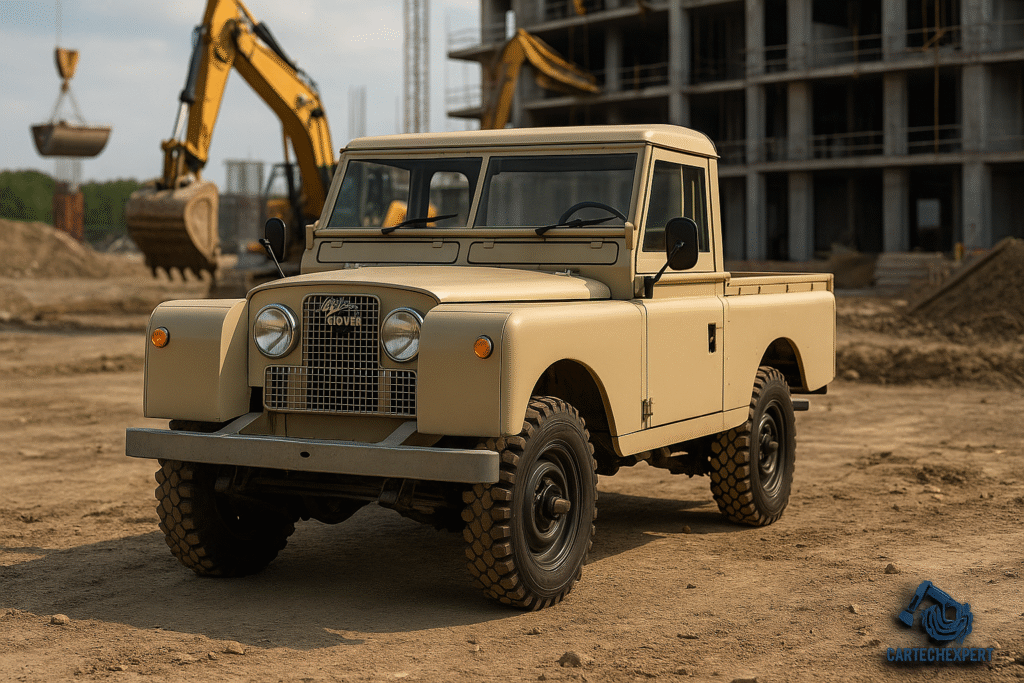

There is a moment every mechanic, engineer, or off-road enthusiast remembers—the metallic door clang of a classic Land Rover, the growl of its diesel engine, the unmistakable vibration through the steering wheel. These trucks were not built for comfort. They were built for work, for mud, for harsh terrain, for survival.

Across farms, deserts, mountain ranges, and military posts, the classic Land Rover became a symbol of endurance. For decades, these rugged machines served as rescue vehicles, expedition platforms, agricultural workhorses, and battlefield companions. The Classic Utility Truck Era is more than a point in history—it is a global engineering legacy.

“Land Rover – The Classic Utility Truck Era” refers to the engineering period spanning roughly 1948–2016, when Land Rover produced simple, durable, body-on-frame utility trucks designed primarily for:

This era includes the Series I, II, III, and the iconic Defender models—vehicles globally recognized for their mechanical simplicity and extreme off-road capability.

The very first Land Rover—Series I—was introduced in 1948. It was conceived as a practical utility vehicle for farms and rural workers. Engineers built it using leftover aircraft aluminum and simple, durable components.

Series I Land Rovers quickly became popular exports and were used by:

Series II improved body proportions, increased cabin space, and introduced new petrol and diesel engines.

Regarded by many mechanics as the toughest of all Land Rovers, the IIA featured:

Series III added improved lighting, full-synchromesh gearboxes, and enhanced interior ergonomics—though still incredibly basic by modern standards.

During the Cold War, various armed forces adopted modified Series trucks for:

The Defender 90, 110, and 130 models adopted modernized mechanical systems but maintained the classic Land Rover utility DNA.

The Defender served as a preferred choice for:

Note: Classic Land Rovers lack modern safety measures—operators must rely heavily on proper maintenance and defensive driving.

| Engine | Type | Output | Era |

|---|---|---|---|

| 2.25 Petrol | I4 | 70–75 hp | Series II/III |

| 2.25 Diesel | I4 | 60 hp | Series Models |

| 200Tdi | I4 Turbo Diesel | 107 hp | Defender |

| 300Tdi | I4 Turbo Diesel | 111 hp | Defender |

| Td5 | I5 Turbo Diesel | 120–135 hp | Defender |

| Feature | Benefit |

|---|---|

| Aluminum body | Corrosion resistance & lightweight strength |

| Ladder-frame chassis | High durability & modular repairs |

| High ground clearance | Extreme off-road capability |

| Simple electrics | Easy field repairability |

Yes—if maintained properly. Their simplicity makes them easy to repair, but they require regular attention.

The 300Tdi is widely considered the most reliable and easiest to maintain long-term.

The steel chassis can rust; aluminum panels resist corrosion but require monitoring around steel contact points.

Yes. The aftermarket for classic Land Rover parts is extremely strong worldwide.

“Land Rover’s classic utility trucks were built for heavy-duty work, off-road durability, and global industrial use.”

Land Rover’s Classic Utility Truck Era represents one of the most important chapters in global automotive engineering. These machines built farms, crossed continents, served in wars, and shaped the identity of rugged utility vehicles worldwide. Their simplicity, durability, and capability still influence modern off-road design today.

To explore more heavy-duty engineering articles, visit:

cartechexpert.com

For tools, diagnostic equipment, and workshop products, shop at:

store.cartechexpert.com