Physical Address

Arthur Avenue , BrookField , ILLINOIS , 60513 , United State

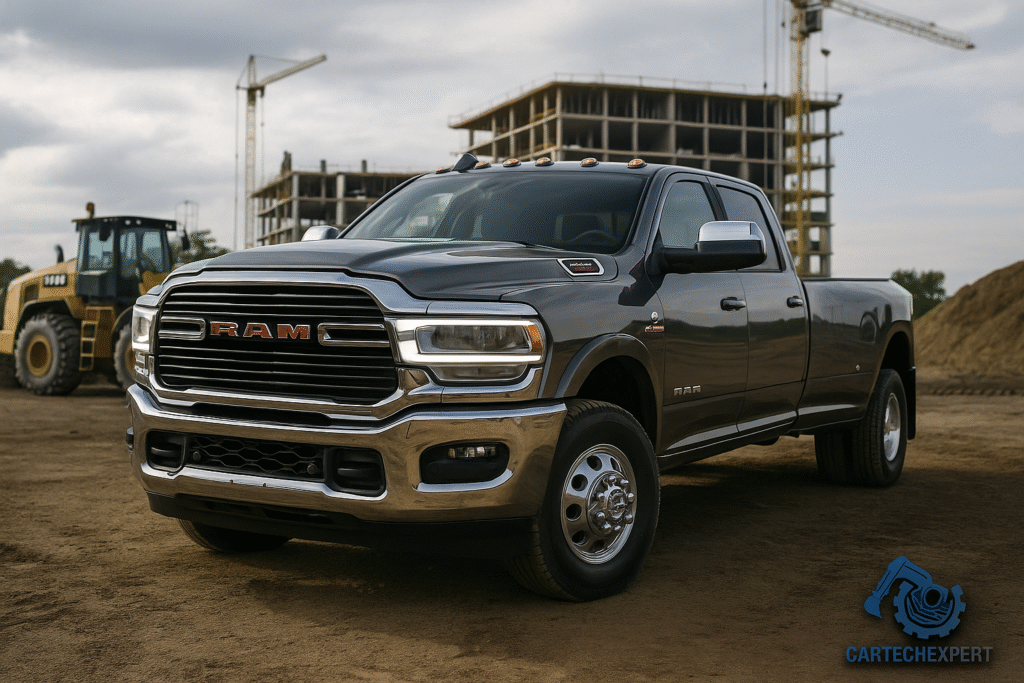

Every technician, engineer, and heavy-equipment operator knows the feeling: the low vibration of a truck idling beside you, the smell of heated steel, diesel, and dust mixing in the air, and that unmistakable moment when you sense—deep in your chest—that this machine isn’t just built for transport. It’s built for work. Hard work.

From oil fields to construction sites, RAM trucks have become the backbone of crews who rely on torque, endurance, and engineering precision. Their legacy begins long before RAM became its own brand—and understanding this evolution helps professionals choose, maintain, and operate these machines with confidence.

The story of RAM trucks begins under the Dodge banner, stretching back to the early 1900s. Dodge was among the first American automakers to engineer heavy-duty chassis capable of supporting commercial and industrial work.

But the name RAM first appeared in 1981, symbolizing power, durability, and American truck identity.

In 2009, Chrysler reorganized its brands, separating “RAM” from Dodge. This decision was strategic—not cosmetic.

This split allowed RAM to evolve into one of the fastest-growing truck brands in North America.

Once separated, RAM quickly began designing trucks specifically for heavy-duty use—including engine platforms optimized for high-load environments and professional use.

Today, RAM trucks are known for their combination of raw power, high torque output, and technology-driven reliability—qualities field operators depend on daily.

Explore diagnostic tools for RAM trucks on our store: store.cartechexpert.com

Proper maintenance ensures RAM trucks deliver full performance in demanding environments. Key best practices include:

Technicians and engineers working with heavy-duty RAM trucks face high-risk environments. Safety protocols are not optional—they’re essential.

| Model | Engine Options | Max Torque | Towing Capacity |

|---|---|---|---|

| RAM 1500 | 3.6L V6 / 5.7L HEMI V8 / EcoDiesel | 480 lb-ft | 12,750 lbs |

| RAM 2500 | 6.4L HEMI / 6.7L Cummins Diesel | 850 lb-ft | 19,990 lbs |

| RAM 3500 | 6.7L Cummins HO Diesel | 1,075 lb-ft | 37,100 lbs |

RAM became its own brand to focus exclusively on trucks and compete more aggressively in the heavy-duty segment.

No. RAM handles trucks; Dodge produces performance cars (Charger, Challenger).

The RAM 3500 with the High-Output Cummins diesel is the towing leader.

Yes. RAM HD trucks are engineered for high torque, heavy loads, and industrial tasks.

The journey from Dodge’s early workhorses to RAM’s modern heavy-duty machines reflects a legacy of strength, innovation, and pure capability. Whether you work in construction, transport, mining, or automotive service, understanding this evolution helps you select and maintain the right truck for demanding professional use.

For more technical guides, diagnostics, and tools, visit CarTechExpert.com