Mitsubishi – From Rally Legends to Modern Hybrid Powertrains

Table of Contents

Introduction — A Brand Forged in Dust, Snow & Hybrid Power

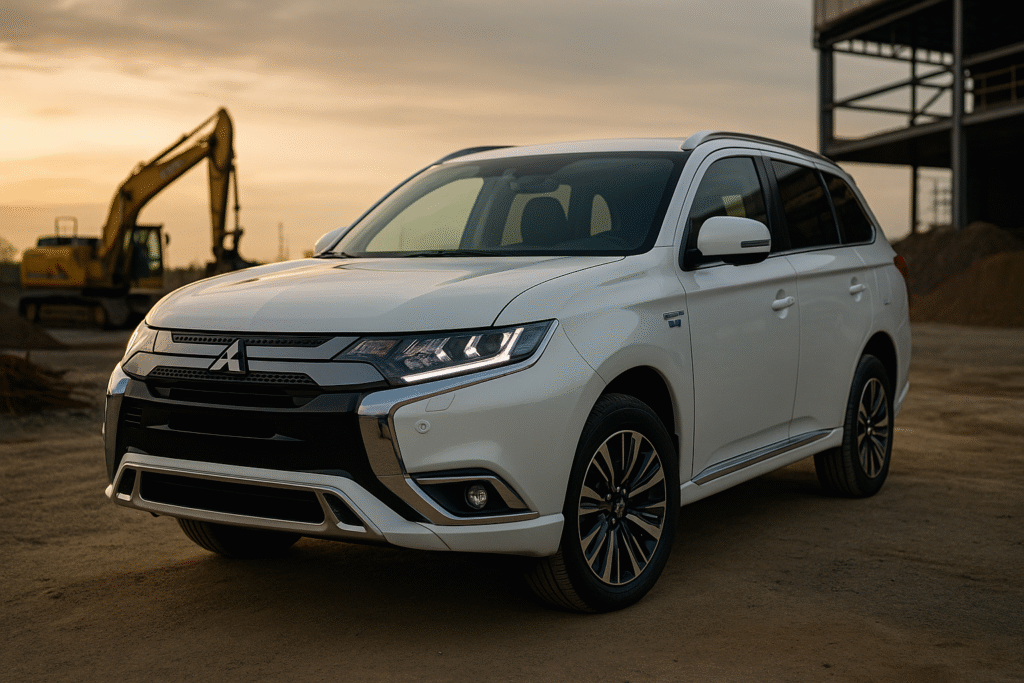

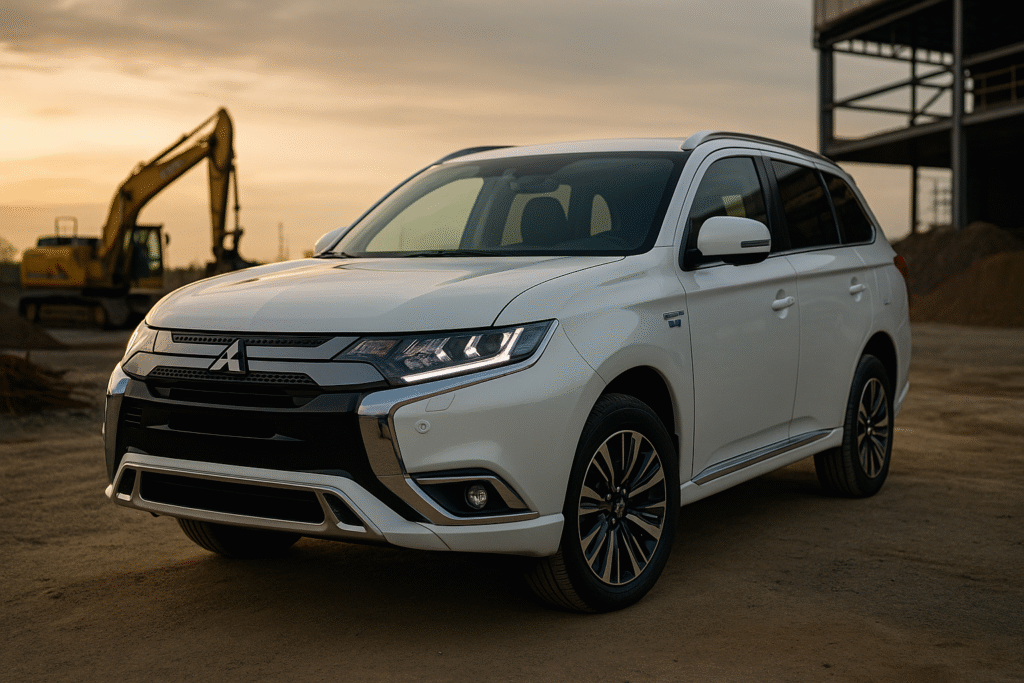

A Mitsubishi pulls into the workshop and you immediately sense its dual nature. Whether it’s a Lancer Evolution with its unmistakable turbo whine, a Pajero built for rugged adventure, or an Outlander PHEV silently rolling in on electric power — Mitsubishi vehicles carry a spirit shaped equally by motorsport grit and modern efficiency engineering.

Technicians who work on Mitsubishi quickly learn that the brand’s engineering philosophy is grounded in robust drivetrains, smart traction systems and practical vehicle design, but in recent years it has shifted toward electrification with remarkable success. The mix of rally-born toughness and hybrid sophistication makes Mitsubishi a unique technical study for workshops worldwide.

Definition: Mitsubishi – From Rally Legends to Modern Hybrid Powertrains

The phrase reflects Mitsubishi’s transition from a performance-driven, rally-dominant manufacturer to a leader in hybrid SUV technology. Key pillars include:

- Rally heritage — decades of engineering from Lancer Evolution and Pajero Dakar programs.

- Advanced 4×4 systems — Super Select 4WD and AWC (All-Wheel Control).

- Turbo engineering — 4G63 and 4B11 engines known for strength and tunability.

- Hybrid & PHEV innovation — Outlander PHEV leading global plug-in SUV sales for years.

Mitsubishi vehicles embody mechanical durability, practical design choices and evolving electrified technology — all of which workshops must understand intimately.

Heritage: Lancer Evolution, Pajero & the Spirit of Rally Engineering

Mitsubishi gained global respect through motorsport. The Lancer Evolution dominated WRC stages with aggressive turbocharged power, finely tuned AWD systems and razor-sharp chassis balance. The Pajero became a Dakar legend, winning the rally multiple times through unmatched durability.

These racing programs influence Mitsubishi’s engineering even today:

- AWC traction logic borrowed from rally control algorithms.

- Turbocharged engine architecture optimized for response.

- Heavy-duty cooling strategies for hot, high-load conditions.

- Suspension geometry designed for both ride comfort and rough-terrain resilience.

Technicians working on Mitsubishi models still benefit from understanding the brand’s rally foundations.

Mitsubishi utilizes a mix of unibody platforms and ladder-frame architectures depending on vehicle purpose.

Unibody Platforms (Lancer, Outlander, Eclipse Cross)

- Lighter weight for fuel economy.

- Integrated crash structures.

- Designed around AWC systems and hybrid packaging.

Ladder-Frame Platforms (Pajero, L200/Strada)

- High rigidity for off-road punishment.

- Separate body structure eases heavy-duty repairs.

- Ideal for towing and commercial use.

Workshops must recognize these differences because service access, torque specs, chassis bushings and lift points vary dramatically.

Drivetrains: Super Select 4WD, AWC & Mitsubishi Traction Systems

Mitsubishi’s drivetrains are among the most respected in the world.

Super Select 4WD

- Allows 2H, 4H, 4HLC and 4LLC modes.

- Use 4H on any surface — unique among 4×4 systems.

- Lockable center differential for harsh terrain.

- Low-range gearing for maximum crawl ability.

AWC (All-Wheel Control)

- Real-time torque distribution.

- Integrated with stability control and ABS.

- Used extensively in Lancer Evolution models.

Technician priorities include:

- Transfer case fluid quality.

- Differential lock actuator inspections.

- Calibration of wheel-speed sensors after service.

- Electronic coupling health checks.

Engine Evolution — 4G63, 4B11 & Modern Turbo Engineering

Mitsubishi engines are legendary in motorsport and tuning culture.

4G63 (Lancer Evolution I–IX)

- Iron block with extreme strength.

- Massive aftermarket support.

- Excellent tolerance to boost pressure.

4B11 (Evolution X)

- Aluminum block for weight reduction.

- Twin-cam, high-flow turbo architecture.

- More efficient but still highly tunable.

Modern Non-Performance Engines

- MIVEC variable-valve-timing systems.

- Small displacement turbo options for efficiency.

- Hybrid-compatible variants for Outlander PHEV.

Workshop focus:

- Turbo oil feed line inspections.

- Timing chain tension monitoring.

- MIVEC actuator calibration.

Hybrid & PHEV Leadership — Outlander PHEV & e-Motor Technology

The Outlander PHEV is the world’s best-selling plug-in hybrid SUV for many years and showcases Mitsubishi’s electrification strategy.

Core Components

- Dual electric motors — one front, one rear.

- High-voltage traction battery — liquid-cooled for longevity.

- Series-parallel hybrid control — enables engine-as-generator functionality.

- Regenerative braking — adjustable via steering-wheel paddles.

Technician priorities:

- HV isolation procedures before service.

- Battery coolant loop checks.

- Electric motor bearing noise assessment.

- Onboard charger diagnostics.

Cooling, Thermal Management & Durability Engineering

Mitsubishi designs vehicles for global markets, requiring strong cooling systems.

- Large radiators for turbo engines.

- High-capacity transmission coolers for towing or off-road use.

- Battery cooling circuits for PHEV systems.

- Intercooler ducting optimized for airflow.

Technicians must inspect:

- Radiator fin contamination (mud, dust, insects).

- Thermostat operation.

- Coolant pump health on hybrids and PHEVs.

- Heat exchanger connections around inverters.

Chassis Dynamics, Suspension & Rally-Derived Tuning

Mitsubishi chassis design emphasizes durability and adaptability.

- MacPherson strut front suspension.

- Multi-link rear systems for stability.

- Stiff anti-roll bars on performance models.

- High ground-clearance geometry for SUVs.

Workshop inspections should target:

- Control arm bushings.

- Shock absorber leaks.

- Ball joint play.

- Bent suspension components from off-road impacts.

Maintenance Strategies & Workshop Best Practices

- Use Mitsubishi-approved oils for MIVEC and turbo engines.

- Inspect spark plugs frequently on turbocharged models.

- Update PHEV software through OEM diagnostic tools.

- Check AWD couplings and transfer case fluids.

- Perform HV battery cooling service on schedule.

Common Issues, Diagnostics & Troubleshooting Insights

Turbo Engines

- Boost leaks from aging hoses.

- Wastegate actuator faults.

- Oil coking in turbo lines if oil changes are delayed.

AWC/4WD Systems

- Wheel-speed sensor faults affecting traction logic.

- Transfer case wear under heavy off-road use.

- Electronic coupling overheating on steep climbs.

PHEV Models

- Cooling pump failures leading to derating.

- Isolation faults due to moisture in HV connectors.

- DC fast-charging connector sealing issues.

Illustrative Tables

Table 1 — Mitsubishi Engine Families

| Engine |

Type |

Strength |

Workshop Focus |

| 4G63 |

Turbo I4 |

Legendary durability |

Turbo oiling, timing components |

| 4B11 |

Turbo I4 |

Lightweight, responsive |

MIVEC & boost control |

| MIVEC NA |

Gasoline |

Simple & reliable |

Valve timing calibration |

| PHEV |

Hybrid/EV |

Quiet & efficient |

HV safety, cooling loops |

Table 2 — Drivetrain Comparison

| System |

Type |

Strength |

Service Notes |

| Super Select 4WD |

Part/Full-Time 4×4 |

Flexible, durable |

Transfer case fluid & actuator checks |

| AWC |

AWD |

Dynamic traction |

Sensor calibration |

| PHEV e-AWD |

Electric AWD |

Instant torque |

Motor diagnostics |

FAQ Section

1. Are Mitsubishi vehicles reliable?

Yes — especially SUV, pickup and turbo models when serviced correctly.

2. Is the Outlander PHEV expensive to maintain?

No — PHEV systems are modular and designed for longevity, but require HV-safe procedures.

3. Are Mitsubishi turbo engines good for long-term use?

Yes, provided oil changes are timely and cooling systems remain healthy.

4. Do Mitsubishi AWD systems require special servicing?

Yes — transfer case, differential and coupling fluids must be monitored closely.

Suggested Past Articles & Useful Links

More articles available at cartechexpert.com.

Professional tools, diagnostic equipment & EV safety gear: store.cartechexpert.com

Conclusion

Mitsubishi’s engineering journey spans from rally-dominant, turbocharged machines to modern electrified SUVs. This blend of motorsport robustness and hybrid innovation creates vehicles that are both capable and technically fascinating. For workshops, Mitsubishi models reward precise diagnostics, correct fluid management, and disciplined HV procedures — ensuring long, reliable service lives across all powertrains.

Thank you for reading.