Physical Address

Arthur Avenue , BrookField , ILLINOIS , 60513 , United State

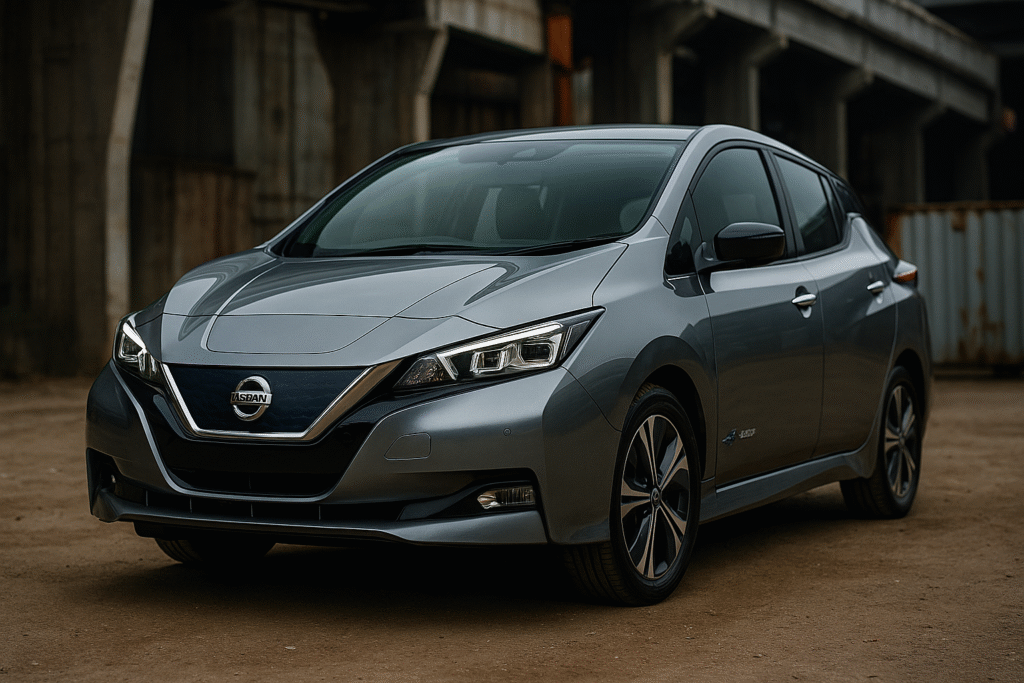

A small hatchback rolls into the service bay almost silently. There is no exhaust burble, no idle vibration. Instead, a low electronic hum under the floor and a battery status display on the instrument cluster tell the technician what matters: state of charge, cell temperature, high-voltage isolation. A few bays down, an older compact sedan sits on a lift, its naturally aspirated engine cooling after a compression test. For many workshops, this mix of conventional and fully electric vehicles is now routine—and Nissan is one of the manufacturers that placed electric mobility at the center of that transition.

From early compact cars to pioneering mass-market EVs, Nissan has consistently pursued efficiency: in fuel use, in packaging, in manufacturing, and, increasingly, in energy management. The company’s trajectory from reliable, pragmatic internal combustion vehicles to globally deployed electric platforms reflects a broader shift in the automotive industry—one where software, battery chemistry, and power electronics sit alongside pistons, gearsets, and differentials.

This article is designed for engineers, technicians, fleet managers, and industrial professionals who need more than marketing slogans. It examines Nissan’s engineering philosophy, explores internal combustion and electrified powertrains with particular attention to e-POWER and battery electric platforms, looks at manufacturing and quality systems, outlines practical maintenance strategies, and highlights occupational safety protocols for workshops dealing with high-voltage systems. It concludes with tables, FAQs, and references to related articles for deeper comparative insight.

“Nissan – Japanese Efficiency & the Rise of Electric Mobility” refers to Nissan’s evolution from a manufacturer of compact, fuel-efficient vehicles to a global advocate and implementer of electric transport solutions. The phrase encompasses:

For professionals, the concept highlights both engineering and operational themes: minimizing energy waste, maximizing available torque and range for users, and managing the lifecycle of more complex electronic and electrochemical components.

Nissan’s origin story is tied closely to Japan’s industrial expansion in the 20th century. Initially focused on practical, compact vehicles for a developing domestic market, Nissan’s early strengths included robust mechanical designs, efficient packaging for tight roads, and vehicles that could be serviced with limited infrastructure. As Japan’s economy grew and exports increased, Nissan positioned itself as a provider of reliable and affordable automobiles tailored to regional preferences across North America, Europe, Asia, and emerging markets.

Throughout the late 20th century, Nissan emphasized:

Faced with fuel economy standards, emissions regulations, and urbanization trends, Nissan intensified its focus on efficient engines and, later, electrification. The launch of the Nissan LEAF marked one of the first serious attempts to bring a fully electric car to mass-market volumes. This positioned Nissan as a reference point in EV deployment, charging infrastructure integration, and battery lifecycle management well before many competitors scaled their own EV portfolios.

Nissan’s engineering philosophy can be summarized in three core priorities:

On the technical level, this means engines optimized for part-load efficiency, drivetrains designed for stop-and-go traffic, and EV platforms tuned for urban and commuter usage without excessive cost or complexity. Nissan also places emphasis on modularity within subsystems—battery modules, e-POWER components, and shared chassis architectures—to streamline manufacturing and service.

Nissan’s powertrain portfolio spans traditional internal combustion engines (ICE), unique series-hybrid architectures like e-POWER, and fully battery electric vehicles. Each class involves distinct engineering principles and maintenance implications.

Nissan has produced a wide range of gasoline and diesel engines with a consistent emphasis on:

In workshops, typical service focuses include timing components (belts or chains), fuel injection system cleanliness, ignition coil and spark plug health, and cooling system reliability. Engines are generally designed for long service life when maintained according to OEM schedules, with particular attention to oil quality and change intervals in turbocharged or direct-injection variants.

Nissan’s e-POWER system is a notable engineering breakthrough in everyday mobility. Unlike conventional parallel hybrids where the combustion engine and electric motor both drive the wheels, e-POWER is essentially a series hybrid: the internal combustion engine operates primarily as a generator to charge the battery and supply electric power, while the wheels are driven solely by the electric motor.

Key engineering advantages:

Technician implications:

Nissan’s LEAF and subsequent electric models use battery packs (typically lithium-ion) with electric drive motors integrated into compact, maintenance-light drivetrains. The emphasis is on:

For technicians, BEVs change the maintenance profile:

Effective EV design is as much about managing heat and voltage as it is about delivering torque. Nissan’s electric architectures rely on structured battery packs, robust battery management systems (BMS), and carefully designed thermal solutions.

Typical Nissan EV packs consist of multiple modules, each containing cells arranged in series-parallel groups. The BMS monitors:

Temperature strongly affects both battery life and immediate power capability. Nissan’s approaches include:

Workshops must be prepared to:

Nissan’s global production network spans plants in Japan, Europe, North America, and other regions. Manufacturing systems emphasize:

In EV manufacturing, additional controls include:

Understanding Nissan’s manufacturing emphasis on standardization and modularity helps workshop staff anticipate component interchangeability and recognize when non-standard parts or procedures could compromise performance or safety.

Nissan’s vehicle architectures use mixed materials to balance cost, mass, safety performance, and corrosion resistance. Typical measures include:

Durability testing underpins material choices—salt spray, cyclic corrosion, vibration testing, and environmental temperature cycling. In the field, technicians must address:

Servicing Nissan vehicles now involves parallel workflows for ICE, hybrid, and BEV platforms. Workshops should adopt structured approaches to ensure safe and efficient work.

Every diagnostic session should begin with:

Nissan EVs and e-POWER variants rely heavily on software optimizations. Technicians should:

High-voltage systems, strong permanent magnets in motors, and dense battery packs introduce new risk categories into workshops. Safety protocols must be integrated into everyday routines.

| Powertrain | Main Components | Primary Service Concerns | Key Workshop Requirements |

|---|---|---|---|

| Conventional ICE | Engine, transmission, fuel & exhaust | Oil quality, timing components, ignition & injection | Standard diagnostic tools, mechanical expertise |

| e-POWER | Generator engine, traction motor, inverter, battery | Engine lubrication, HV safety, inverter cooling | ICE + HV training, OEM diagnostics, insulation testers |

| BEV (e.g., LEAF) | Battery pack, motor, inverter, reduction gear | Battery SOH, thermal management, HV isolation | HV workshop procedures, BMS diagnostics, specialized PPE |

| Task | Applies To | Priority | Details |

|---|---|---|---|

| Full system scan (all ECUs) | All vehicles | High | Baseline step; captures events across ICE, EV, and body systems |

| HV isolation check | e-POWER & BEV | High | Required before HV component work |

| Battery SOH & temperature analysis | BEV | High | Identify degradation patterns and cooling issues |

| Oil & filter condition review | ICE & e-POWER | High | Critical for engine and generator longevity |

| Software version verification | All modern models | Medium–High | Ensure latest calibrations are installed; reduces repeat complaints |

In e-POWER systems, the internal combustion engine primarily acts as a generator, and the wheels are driven exclusively by the electric motor. This differs from parallel hybrids, where the engine can directly power the wheels. As a result, e-POWER vehicles feel similar to pure EVs in terms of drivability while still utilizing gasoline as an energy source.

BEVs have no oil changes or exhaust systems but require high-voltage safety measures, battery and thermal system checks, and vigilant inspection of electrical connectors and cabling. Suspension, brakes, and tires still require attention, often with slightly different wear patterns due to battery weight and instant torque.

Many Nissan EV packs are modular, allowing replacement of individual modules under specified conditions. However, procedures must strictly follow manufacturer guidelines, including isolation, mechanical support, and recalibration of the BMS where required.

Range issues can stem from battery aging (SOH decline), incorrect tire pressures, wheel alignment problems, excessive accessory loads (HVAC), outdated software, or driving style. Workshops should evaluate all these factors with both diagnostic tools and basic mechanical checks.

Fleet managers should develop tailored maintenance schedules for HV systems, train drivers on EV-efficient operation, invest in appropriate charging infrastructure, and coordinate with workshops that have certified EV technicians and OEM diagnostic equipment.

To deepen your understanding of automotive manufacturing philosophies and reliability strategies, we recommend reviewing earlier articles in this series:

For access to these articles and more advanced technical resources, visit our main website: cartechexpert.com

To obtain workshop tools, diagnostic templates, and training materials tailored to ICE, hybrid, and EV platforms, explore our store: store.cartechexpert.com

Nissan’s journey from practical, efficient combustion vehicles to a leader in electric mobility illustrates the broader transformation of the automotive sector. For engineers and technicians, the brand’s story provides clear action points: mastering high-voltage safety, integrating software and hardware diagnostics, and maintaining disciplined procedures for both legacy and advanced systems.

Key takeaways for professionals:

If this article has supported your technical understanding or workshop planning, share it with your team and incorporate its checklists into your internal SOPs. For more in-depth technical modules, structured training, or assistance in building EV-ready maintenance programs, connect with us through our website and explore our specialized resources.

Thank you for reading.