Physical Address

Arthur Avenue , BrookField , ILLINOIS , 60513 , United State

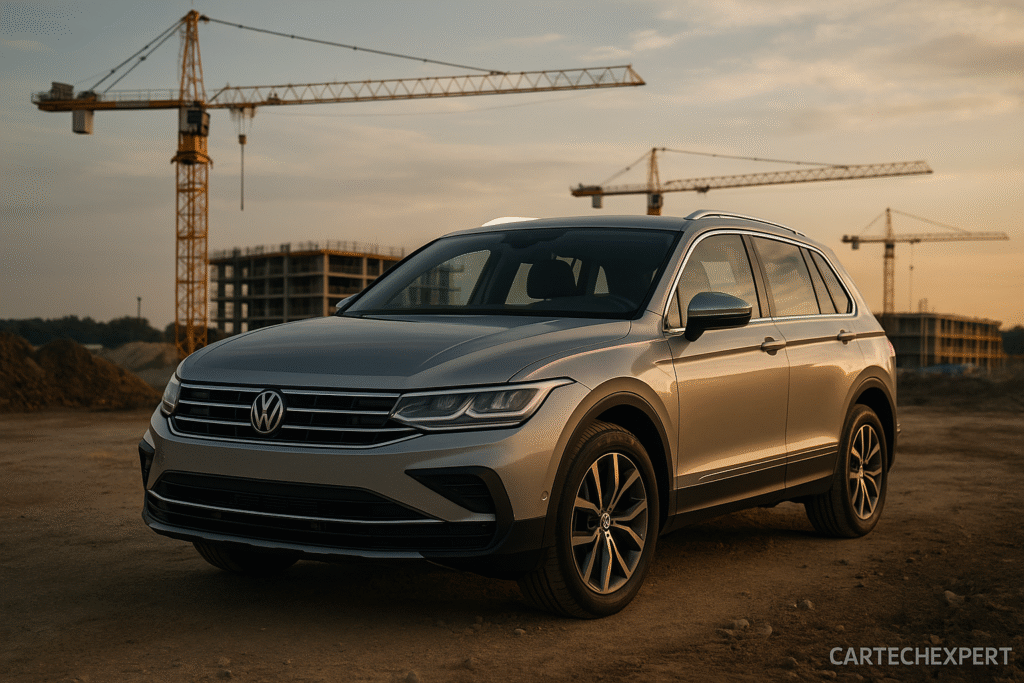

The diagnostic lamp illuminates a dashboard and a technician reads CAN bus frames as a test route concludes. In the background, an assembly cell hums with conveyors and robotic arms, and the tempo of industrial manufacture marks the difference between artisanal production and global scale. Volkswagen’s story is the story of scaling mobility: creating an affordable car that became a cultural icon, then evolving into an industrial conglomerate shaping global automotive manufacturing, electrification, and platform engineering. For engineers, technicians, and production specialists, Volkswagen provides a study in platform standardization, mass-production quality control, and the engineering tradeoffs necessary when moving from single-model craftsmanship to multi-brand, multi-segment manufacturing.

This article examines Volkswagen’s evolution from the original “people’s car” concept to a global automotive giant. It focuses on engineering, production strategies, powertrain evolution, maintenance and service best practices, safety protocols, and metrics that technicians and managers can apply in real-world workshops and production lines. The analysis is technical and practical, intended for professionals who need actionable insights rather than marketing summaries.

Volkswagen – People’s Car to Global Automotive Giant is a framing that encapsulates the brand’s transformation. It includes:

The phrase emphasizes both cultural origins and contemporary engineering realities: scale, standardization, and the technical management of complexity across brands and markets.

Volkswagen’s roots lie in the concept of an affordable, robust vehicle for mass ownership. The early Beetle was engineered for simplicity, mechanical reliability, and ease of maintenance—attributes that made it both popular and resilient across harsh operating environments. As the company expanded through the 20th century, Volkswagen Group acquired and created additional brands (Audi, Škoda, SEAT, Porsche, Bentley, Lamborghini, and others), shifting its strategy toward platform sharing and modular engineering to maintain product diversity while controlling costs and complexity.

Key historical milestones that shaped Volkswagen’s modern engineering posture include:

These shifts represent engineering responses to market scale demands: a unifying set of interfaces and modular components reduce R&D redundancy, shorten time-to-market, and simplify maintenance logistics for technicians servicing thousands of variants worldwide.

The core engineering philosophy at Volkswagen Group centers on modularity, standardization, and platform-first design. Platform engineering is the discipline of defining common structural, electrical, and software interfaces so that multiple vehicle variants can be created with minimal bespoke engineering. The advantages are clear for large-scale manufacturing:

Three platform strategies are particularly relevant:

MQB standardizes the placement of the engine, transmission, and front axle components for transverse-engine vehicles. By fixing a set of interface points (pedal box, windshield position, etc.), MQB enables diverse body styles while keeping key assembly processes identical across models.

MEB is a dedicated EV platform with flat battery packaging, standardized battery modules, and scalable thermal systems. Designing a vehicle from the ground up as an EV reduces compromises otherwise required when adapting ICE platforms to electric drivetrains.

MLB (modular longitudinal matrix) and other scalable backbones support larger vehicles and high-performance arrangements. A unified architecture for longitudinal engines simplifies production of premium models with different power outputs and drivetrains.

Volkswagen’s global manufacturing network relies on standardized process controls, digital integration, and continuous improvement to keep product quality consistent across continents. Essential manufacturing characteristics include:

Quality control metrics commonly tracked by VW plants include first-pass yield, DPMO (defects per million opportunities), and OEE (overall equipment effectiveness). Effective quality systems combine automated inspection (vision, laser, acoustic) with human final checks to capture both measurable and subjective criteria (fit, finish, tactile feedback).

Volkswagen’s powertrain evolution demonstrates adaptation: simple, durable air-cooled engines gave way to water-cooled units, forced induction, advanced direct injection, and now full electrification. Understanding these phases is essential for maintenance, diagnostic planning, and long-term fleet strategies.

Transition toward turbocharging and direct injection provided higher thermal efficiency and torque density. However, these systems introduced complexities:

Volkswagen’s TDI engines offered high thermal efficiency and torque. Maintenance focus areas included high-pressure injection systems, EGR function, DPF (diesel particulate filter) behavior, and turbocharger health. Post-2015 regulatory and product shifts changed the diesel landscape; technicians still encounter legacy TDIs and should be familiar with their service nuances.

Mild-hybrid and plug-in hybrid systems offer torque assistance, regenerative braking, and reduced fuel use. Integration challenges include high-voltage electrical safety, battery state-of-health evaluation, and ensuring correct charge/discharge cycling for longevity.

MEB vehicles use battery packs integrated into the floor, electric drive units optimized for thermal and mechanical efficiency, and power electronics designed for modular assembly. Service implications include:

To balance cost, performance, and safety at scale, Volkswagen employs mixed-material strategies and localized reinforcement. Notable materials engineering practices include:

Durability validation regimes include accelerated corrosion tests, multi-axis fatigue rigs, and climatic chambers simulating humidity, salt spray, and thermal cycling. For technicians, attention to corrosion-prone components (drain paths, plug seals, connector backshells) is vital to avoid early electrical failures in high-mileage units.

Supporting large fleets and retail customers requires efficient, repeatable maintenance programs. Volkswagen service best practices emphasize diagnostics, OEM procedures, and parts traceability.

Begin with full data capture: retrieve fault codes from all relevant control modules (powertrain, ABS/ESP, body, HVAC, battery management) and record freeze-frame and waveform data where applicable. Use OEM-level diagnostic tools to ensure accurate parameter readings and access to relearn procedures.

Safety in high-volume repair and production environments is non-negotiable. Volkswagen-level workshop safety includes:

Regular staff training on HV safety, chemical handling, and mechanical hazard awareness reduces incident rates and protects both technicians and vehicles.

| Platform | Primary Use | Key Advantages | Workshop Implications |

|---|---|---|---|

| MQB | Transverse ICE/hybrid compact to midsize | High parts commonality, reduced R&D per model | Standardized procedures, shared parts kits, easier technician cross-training |

| MLB | Longitudinal engines, premium/larger models | Supports high-torque arrangements and AWD | Requires specific toolsets for longitudinal components and driveline balancing |

| MEB | Dedicated EV platform | Optimized packaging, simplified thermal layout | HV safety protocols, battery diagnostics, and inverter cooling maintenance |

| Service Item | Typical Interval | Notes |

|---|---|---|

| Engine oil & filter | 10,000–15,000 km (varies by engine) | Use specified viscosity and ACEA/API standards |

| High-pressure fuel system inspection | Variable — inspect during major services | Contamination causes injector failure and misfire |

| Timing chain tensioner check | 120,000–160,000 km (or diagnostic indication) | Non-serviceable in some variants—replace per bulletin |

| Battery coolant & HVAC filter | 24–36 months | Proper coolant prevents thermal events and maintains battery life |

Volkswagen emphasizes platform modularity, process standardization, and large-scale manufacturing optimizations to deliver a broad portfolio of vehicles efficiently while maintaining quality and serviceability.

MEB requires HV safety capabilities, battery state-of-health diagnostics, inverter and motor cooling loop maintenance, and updated software toolsets for power electronics calibration.

Yes—MQB shares many mechanical mounting points and component interfaces; however, differences in engine family, turbocharging, and electronics mean technicians must still reference specific model procedures and software versions.

Implement compartmentalized training, ensure separate tooling and PPE for HV work, schedule preventative battery assessments for EVs, and use telematics to monitor component performance across platforms.

For comparative insights into manufacturing philosophies and reliability engineering relevant to Volkswagen, consider reading the following articles on our site:

Visit our main site for the full articles: cartechexpert.com

Access tools, templates, and training packages at our store: store.cartechexpert.com

Volkswagen’s path from the people’s car to a global automotive giant is instructive for engineers and technicians navigating modern automotive complexity. The strategic adoption of modular platforms (MQB, MEB), rigorous manufacturing controls, and a layered approach to powertrain evolution enable Volkswagen to deliver diverse vehicles at scale. For service professionals, the key takeaways are:

If this article supports your team, share it with workshop staff and fleet managers. For fleet-specific SOPs, training modules, or workshop toolkits designed to support MQB and MEB vehicles, visit our store or contact us through our website.

Thank you for reading.