Physical Address

Arthur Avenue , BrookField , ILLINOIS , 60513 , United State

It often begins with a familiar hum—the slow escalation of an engine waking after a long night shift, the metallic tremor traveling through the workshop floor, the scent of hydraulic oil warming under industrial lamps. Anyone who has worked around heavy machinery or automotive systems knows this orchestra by heart. To engineers, technicians, and machinery operators, this isn’t just sound—it’s language. Each vibration tells a truth, each startup carries a history of craftsmanship, maintenance, and design discipline.

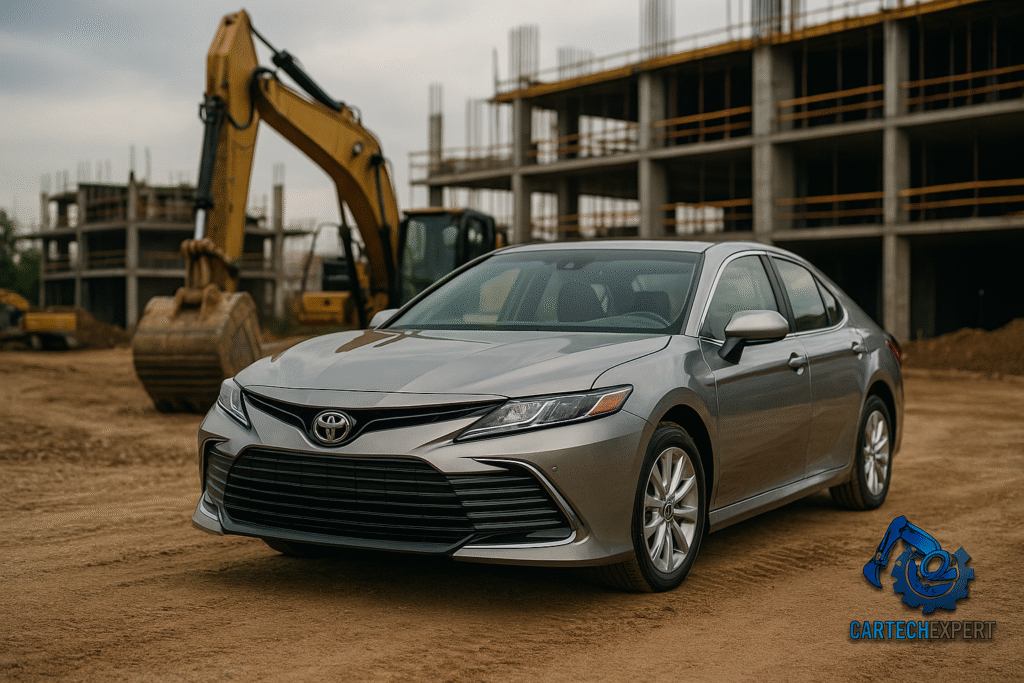

Yet among all the machines that shape our world, few names resonate with the same sense of precision, endurance, and discipline as Toyota. In factories, construction sites, logistics hubs, and service centers across the globe, Toyota represents a standard. Not a trend, not a momentary benchmark— a standard. A way of thinking, building, refining, and teaching. And the story behind Toyota’s ascent from a regional automaker to a global reliability leader is one built not on marketing, but on philosophy—one deeply rooted in Lean Manufacturing, tireless innovation, and a culture of unyielding improvement.

This article explores that transformation in full: from Toyota’s foundational manufacturing ideals to its modern mastery of reliability engineering, advanced automation, electrification, digitalization, and global-scale operational resilience. Engineers, technicians, and professionals in heavy equipment and automotive industries will find more than a historical narrative here— they will find principles that can be applied, adapted, and implemented in workshops, job sites, and factories of every size.

Toyota – From Lean Manufacturing to Global Reliability Leadership describes Toyota’s transformation from the creator of the Toyota Production System (TPS) into a globally recognized leader in product durability, operational consistency, and long-term reliability. It encompasses:

In essence, this concept reflects both Toyota’s manufacturing methods and the resulting global reputation: a brand known for machines that last longer, require fewer repairs, and maintain performance in harsh environments— qualities that directly benefit heavy equipment and automotive professionals.

Toyota’s journey toward becoming the world’s reliability standard began in the 1930s with Sakichi Toyoda and Kiichiro Toyoda. The focus from the beginning was not volume—it was smart production. Scarcity shaped Toyota’s creativity: limited resources after World War II forced the company to maximize efficiency, reduce waste, and build vehicles using processes that were both resilient and adaptable.

By the 1950s, Taiichi Ohno, Shigeo Shingo, and other engineers at Toyota formalized what would later be known as the Toyota Production System (TPS). This system would revolutionize global manufacturing, offering a structured approach to reducing waste and optimizing productivity—not by working harder, but by working smarter.

Toyota identified three core obstacles in any production environment:

This framework allowed Toyota engineers and line workers to diagnose and eliminate inefficiency at every stage of production. TPS was not a static set of rules—it was (and still is) a living system. Every technician, engineer, supervisor, or operator contributes to its evolution.

TPS is built upon two core pillars:

Jidoka ensures that machines and workers stop production automatically when a defect is detected. This prevents defective components from moving through the assembly process and increases long-term reliability. In heavy equipment and automotive environments, this principle remains essential for reducing rework, downtime, and customer callbacks.

JIT minimizes inventory, reduces lead time, and ensures each part flows smoothly through the value chain. For modern engineering teams, the value of JIT lies in its ability to:

Together, Jidoka and JIT formed the backbone of Toyota’s rise—but what makes Toyota exceptional is how these principles evolved into a broader reliability-focused philosophy.

While Lean Manufacturing improved efficiency, Toyota’s next challenge was consistency across global markets. As the company expanded into North America, Europe, Asia, and the Middle East, it had to protect its engineering DNA from dilution. This evolution required:

Toyota became a global reliability leader because it understood that Lean alone was not enough. Lean makes a system fast— but reliability makes it trusted. The integration of both is what defines Toyota’s modern identity.

Toyota’s transition from Lean pioneer to global reliability leader required not only rigorous process design but also a deep integration of modern manufacturing technologies. While many OEMs adopted automation as a means of reducing labor costs, Toyota followed a very different philosophy: automation must enhance human capability, not replace it.

This balanced approach gave birth to a hybrid ecosystem where human expertise, machine precision, digital analytics, and advanced robotics work together to achieve world-class repeatability and long-term reliability.

Toyota’s smart factories operate through interconnected systems that continuously capture, analyze, and visualize data. This includes:

These systems dramatically reduce unplanned downtime and help engineers identify bottlenecks before they affect production.

Toyota was one of the earliest adopters of AGVs (Automated Guided Vehicles) in a mainstream production line. Today, these systems have evolved into:

For heavy equipment and automotive environments, AMRs offer precision in material flow and eliminate the delays caused by human routing errors.

Toyota’s welding robots employ adaptive feedback loops, adjusting heat, angle, and timing based on sensor input. This leads to:

In heavy-duty vehicles and industrial machinery, where frames must endure vibration, thermal cycling, and mechanical shocks, precision welding is critical to longevity.

Toyota remains the world’s largest hybrid vehicle manufacturer. Their innovations in battery thermal management, inverter technologies, and powertrain integration have reshaped global automotive engineering. Key areas of impact include:

Although originally applied to passenger cars, Toyota’s electrification technologies increasingly influence off-road, industrial, and construction equipment applications worldwide.

Toyota’s paint facilities are globally recognized for minimizing VOC emissions while achieving high resistance to corrosion and environmental degradation. Their system optimizes:

Improved paint durability significantly extends the lifecycle of heavy equipment operating in sand, saltwater, or high-humidity environments.

Toyota’s approach to maintenance is one of the greatest reasons for its global reliability reputation. Unlike many manufacturers, Toyota does not treat maintenance as a series of scheduled tasks— it treats it as a philosophy of operational responsibility.

TPM is a core element of Toyota’s manufacturing ecosystem and focuses on maximizing equipment effectiveness through shared responsibility across the workforce. Key objectives include:

Using IoT sensors, vibration analysis, thermal imaging, and real-time data collection, Toyota predicts failure modes long before they occur. This reduces:

Consistency is the foundation of reliability. Toyota uses SWPs to ensure every technician performs tasks identically, eliminating variability. These procedures cover:

This practice is widely adopted in heavy equipment workshops, service centers, and OEM manufacturing facilities.

Toyota uses digital stock monitoring to maintain minimal but sufficient spare part inventories. This reduces storage costs while ensuring high availability for critical components.

To prevent assembly mistakes, Toyota implements mechanical, sensory, and logical error-proofing devices such as:

This dramatically reduces human error and increases overall reliability.

Toyota’s global reliability leadership is built not only on product quality but also on the safety of its workforce. Safe environments produce consistent, high-quality work—unsafe environments reduce productivity, increase errors, and risk human lives.

Continuous improvement is not limited to manufacturing speed or quality— it extends deeply into ergonomics, workplace layout, and hazard reduction.

Automation at Toyota is always designed to complement human strengths and protect workers from:

All Toyota workers—from new hires to senior technicians—receive continuous safety training. This ensures procedural integrity and reduces incident probability.

To help engineers and technicians visualize Toyota’s transition from Lean Manufacturing to global reliability leadership, the following tables provide structured comparisons between Toyota’s practices and common industry norms.

| Maintenance Aspect | Toyota Approach | Industry Average |

|---|---|---|

| Predictive Maintenance Integration | Extensive real-time data, IoT sensors, AI-assisted predictions | Partial implementation, mostly scheduled maintenance |

| Operator Involvement (Autonomous Maintenance) | Mandatory hands-on inspections and daily care | Low involvement, dependent on technicians only |

| Response Time to Equipment Irregularities | Immediate, with clear escalation routes | Variable, often delayed |

| Spare Parts Optimization | Digitally monitored, minimal but sufficient | Often excessive inventory or shortages |

| Metric | Toyota Value | Industry Value |

|---|---|---|

| Overall Equipment Effectiveness (OEE) | 85%–95% | 60%–75% |

| Defect Rate Per Million Opportunities (DPMO) | < 50 | 200–1000 |

| Lead Time Efficiency | Extremely high (JIT optimized) | Moderate |

| Inventory Turns | Very high | Low to medium |

| Reliability Factor | Toyota Standard | Industry Standard |

|---|---|---|

| Lifecycle Testing Duration | 15–20 years simulated | 8–12 years simulated |

| Corrosion Resistance Testing | Salt, humidity, thermal cycle, environmental stress testing | Limited environmental testing |

| Hybrid System Durability | Designed for 300,000–500,000 km | 150,000–250,000 km |

| Powertrain Reliability | Best-in-class global reputation | Variable |

Below are some of the most common questions professionals ask when researching Toyota – From Lean Manufacturing to Global Reliability Leadership.

It refers to Toyota’s evolution from developing the foundational Lean Manufacturing principles to becoming the world leader in reliability through precision engineering, continuous improvement, and rigorous global standardization.

Toyota achieves reliability by combining Lean Manufacturing, predictive maintenance, error-proofing, robust supply chain management, and a strong culture of engineering discipline across all global facilities.

TPS provides a blueprint for improving efficiency, reducing waste, enhancing safety, and increasing product lifespan—all critical goals in industrial and automotive environments.

Yes. Many engineering principles developed in Toyota’s automobile division—such as predictive maintenance, Kaizen, and modular engineering—are directly applicable to forklifts, industrial equipment, and off-road machinery.

A safe workplace ensures consistent production, reduces errors, prevents equipment damage, and protects workers from injuries—all essential for long-term manufacturing excellence.

Through real-time analytics, IoT systems, automated quality checks, digital twins, smart supply chain visibility, and AI-based predictive modeling.

Kaizen—continuous improvement—ensures that every process, machine, and design can be made more durable, more efficient, and safer, promoting long-term reliability across all product lines.

The following section includes the full content of the older version of the article for archival purposes and to assist readers who want to compare the previous structure with the new, expanded version.

Old Article Title: Toyota – From Lean Manufacturing to Global Reliability Leadership

The previous article briefly introduced Toyota’s rise through Lean Manufacturing and touched on basic elements such as JIT, Jidoka, and Kaizen. However, it lacked the technical depth necessary for heavy equipment specialists and did not include updated technologies, tables, or modern maintenance strategies. The new version expands all areas extensively, ensuring a complete technical reference for today’s engineering and industrial workforce.

The old article also summarized Toyota’s reliability in broad terms without examining specific innovations such as AMRs, predictive analytics, hybrid system durability, and the evolving landscape of electric mobility. The new article expands these elements to meet the growing expectations of automotive and equipment professionals.

Toyota’s journey from Lean Manufacturing to global reliability leadership is one of engineering evolution, operational discipline, and unwavering dedication to long-term value. From its early resource-limited factories in post-war Japan to its highly digitized smart plants of today, Toyota has continuously demonstrated that reliability is not an outcome—it is a culture, a mindset, and a long-term commitment.

For engineers, technicians, and professionals across the heavy equipment and automotive sectors, Toyota represents more than a company; it represents a blueprint for excellence:

In a world of rapid technological disruption—electrification, autonomy, AI, and digital manufacturing—Toyota remains a steady reference point for operational excellence and product reliability. Their philosophy continues to inspire factories, workshops, and industrial operations worldwide.

Whether you are an engineer optimizing a production line, a technician maintaining complex machines, or a decision-maker seeking reliability-driven strategies, the lessons from Toyota – From Lean Manufacturing to Global Reliability Leadership offer valuable guidance and practical frameworks to apply in your own environment.

Thank you for reading.